|

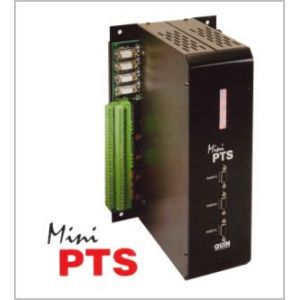

Quin PTS MK2 - Machine Control Centre THE ULTIMATE MACHINE CONTROL SYSTEM The PTS MK2 is a powerful machine control system which organizes and generates the motions within a machine, as well as interfacing to external plant I/O and, most importantly, the man machine interface.The Programmable Transmission System (PTS) software comes into its own when the machine designer is faced with developing a multi-axis synchronized system, where external I/O - via a simple or complex PLC – has to interface and play an important part in the overall operation of the machine.

48 Axis PTS MK2 System The PTS language simplifies this often very complex task. Traditional mechanical machines require significant modification over time, often with many change parts. Using the PTS, the machine designer can develop a flexible machine which caters for changing product cycles. The PTS handles product changeovers in seconds and, because the motion control is closed-loop, any wear in the machine is compensated. The PTS also meets the special demands of modern materials and higher operating speed. Accurate tension control is now an essential QA parameter, and in high-speed printing or packaging applications registration control is vital. The PTS handles both tension and registration control accurately and simply, completely eliminating mechanical set-ups. The PTS has been developed specifically to meet today’s requirements for high operating speeds and flexibility to manufacture wide range of products with consistent product quality.

|

|

|

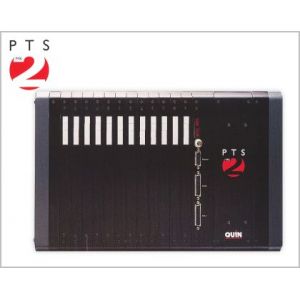

16 Axis PTS MK2 System

|

Features

|

|

Diagnostic and machine set-up: Using the Online tuning screen, Motors and Drives can be quickly tuned to provide optimum performance. The Windows tuning screen eliminates the need for oscilloscopes and provides the additional function of a position error trace. The various gain parameters can be varied and the results are immediately visible.

|

|

|

The PTS MK2 System integrates with multiple Q-Drives or independently sourced drives. The Specialist Diagnostic Software allows for local or remote system diagnostics via a modem. High speed communication between racks via Servonet enables the simpler integration and close synchronisation of the large line/area based system.

Application Examples Labelling Machine

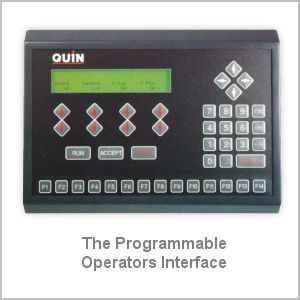

The above application is controlled from a Quin Operator's Panel. This allows the operator to control the machine and also to specifiy the machine set-up. PTS Scope, running on the PC, allows the motion and timing of the system to be accurately set up and monitored.

Wrapping Machine

PTS Motion allows motion profiles to be graphically generated and downloaded to the PTS control system. Each profile can be quickly produced to suit a particular product set-up. This operation can be done either off-line or interactively.

|

|

Company

Company