|

Quin SERVOnet THE REMOTE CONTROL OF POWER HAS NEVER BEEN SO FLEXIBLE! SERVOnet is a method of networking distributed servo control in a machine. A central Machine Controller acts as a programme store, communications centre and scheduler to a number of networked axis modules which perform servo control on a range of motors. This follows the philosophy of all successful management-effective delegation. The definition of servo within SERVOnet encompasses almost any type of motor - AC asynchronous, DC brushed and Stepper in addition to brushless AC. Servo means they can be controlled and synchronised together regardless of type or manufacturer used.

|

|

|

Features

|

|

The SERVOnet System SERVOnet offers a revolution in the design of machines. Instead of One large assembly, a machine can be conceived as a system of modules which can be:

|

|

|

|

|

All conventional network fascilities are available, but SERVOnet has the added capability of sequencing up to 60 nodes of servo control without sacrificing the robust strength of the lineshaft. SERVOnet can provide improved accuracy and machine error detection with increased flexibility of use.

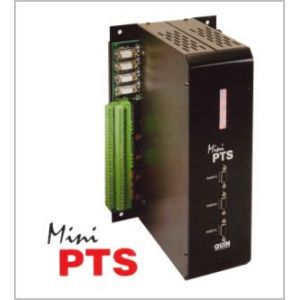

Adding other motors and drives Other types of drive can also be added to SERVOnet including inverters, DC drives or hydraulics. By connecting the Mini-PTS 3 to SERVOnet, up to 3 analogue controlled drives can be added to one SERVOnet node and are supported by digital and analogue inputs and outputs. To the Machine Controller they look just like 3 more Qdrives and support identical motion functions. Different drive types can therefore be integrated together in a seamless manner.

|

|

Company

Company