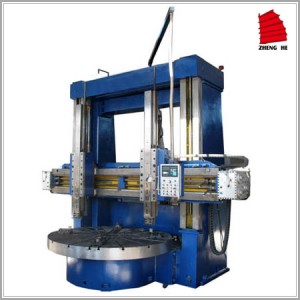

The CNC double column vertical lathes uses the most advanced lathe producing technology,modularized designed,finite-element analysis,together machine,electricity,hydraulic in one set, to reflect high accuracy precision cutting.

Lathes adopts Simens 802DSL or 802C CNC system.CNC at the same time,it has 100% full manually exchange operation function.,though common operator can also don't need programme,manually operation,convenient and practical.Second gears mechanical speed changing plus huge torque DC electrical motor stepless speed governing,to reflect constant linear speed turning.

The lathes use high quality castings(HT300)which after a heat timeliness processing.The above guide rail on the crossbeam is crustificated with chrome, wolfram,and manganese plate.

The left tool carrier is a normal one,and the right is CNC controlled,and can be both CNC controlled.The guide rail of worktable uses import ed constant current motor to supply oils constantly,stable accuracy;The hydraulic oil uses refrigerator to refrigerate at a stable temperature,and lower the worktable deformation.

Each lubrication part of Lathes uses automatic lubrication pump to supply oils automaticlly.High accuracy ball screw,uses import ed bearings(Germany INA)to support.

Both the lathes design and manufacture are strictly according to JB/T9934.1-1999 CNC vertical lathe accuracy test standard and JB/T9934.2-1999 CNC vertical lathe technical conditions.

Our company has a completed service system(before sales,in sales,after sales,installation,

debugging,training and repair guaranteed),two year warranty service.

The lathes use a large amount of functional parts(electrical parts,servo motor,servo driver,hydraulic parts,bearings,screw,planetary reducer,etc.),reliable quality warranted.The transmission case adopts high accuracy grinding gears.

Lathes standard configuration with white steel crossbeam as defended,and walking board also.

Company

Company