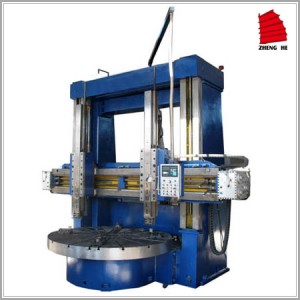

The double column vertical lathe machine uses modularize design ,general used products, mature , stable and reliable.

The lathes' high quality castings (HT300) has a heat timeliness processing .The guide rail surface of crossbeam has a super audio quench processing,the vertical tool use ductile iron material,the sliding surface use model pasting processed,lasting and durable.The handed lubrication pump realize that each lubrication part can lubricate by inject oils.High quality and famous electricity parts and Japan Omron PLC controlled,with high reliability.

The guide rail of vertical lathe has two kinds,one is moving-static pressure,the other is static pressure,the moving pressure kind can bear10tons,the static pressure kind can bear 16-20tons.Independent hydraulic station,convenient for adjust,repair and maintenance.Standard equipped with raster digital displayed configuration.

Both the lathes design and manufacture are strictly according to JB/T4116-96 vertical lathe accuracy test standard and JB/3665-96 vertical lathe technical conditions.

Completed processing and configuration crafts,strict quality controlled process to make sure a perfect product with super high quality.

The vertical lathe has high accuracy transmission case gears(level 6 accuracy)and high accuracy grinding spiral umbrella gears(level 6 accuracy),low noise,and smooth operation.

One year quality guaranteed service(installation ,debug and after-sales service).

Company

Company