Wrap-Around Labeling

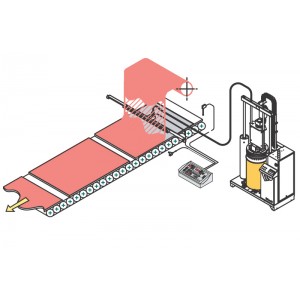

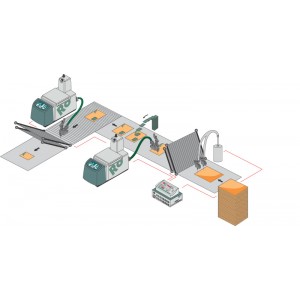

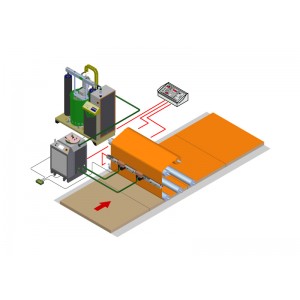

The hotmelt nozzle application system sticks cut wrap-around labels reliably onto glass, sheet metal and plastic containers. The start of gluing is sprayed on the container in form of several small spots of glue arranged in a spiral.

The applied spiral/swirl of adhesives ensures that the rotating container picks up a label from the magazine. At the same time the slot-type nozzle applies a thin strip of glue to the end of the label. The label is now wrapped around the bottle and precisely glued where the end will overlap.

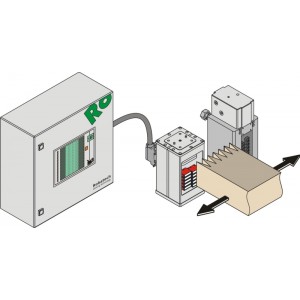

The precise, controlled glue application by nozzle technology offers evident advantages versus the traditional roller technology and can be retrofitted.

Robatech systems are featuring

- Closed system

- Considerable adhesive savings compared with roller application

- Precisely controlled glue application for superior productivity

- Easy and rapid change-over to other formats

- Adhesive is protected from ambient air and contaminations

- Less cleaning and higher safety due to closed system

- Trouble-free processing of plastic labels

- Stable and functional bracket system

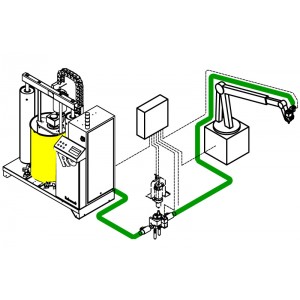

Robatech Nozzle Application System

- Concept-series hotmelt appliance

- Built-in pattern control

- Spiral application head

- Adjustable labelling head

- Bracket system for head positioning

- Option: Granule feeder

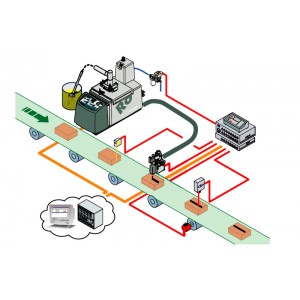

- System Integration into the host machine:

RobaPAR, SNMP, Ethernet, CAN-Bus or Profibus

Leaflets