Edge Banding

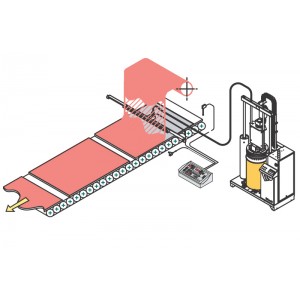

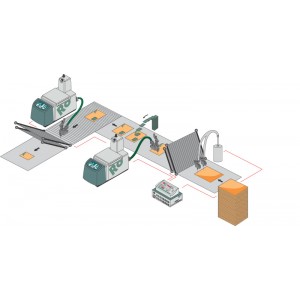

Panels for kitchen- or bathroom cabinets, counter top or room partitions are typically manufactured by glueing a band strip of PVC, ABS, veneer, aluminium, paper or solid wood onto the board edge. EVA, polyolefin’s or reactive PUR hotmelts for higher demands like for waterproof glued connections can be applied.

In traditional edgebanding machines, in the roller coater-technique the PURHM adhesive is exposed to contamination from the chipboard, has a shorter pot-life

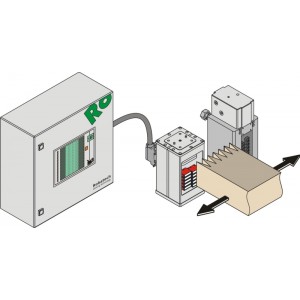

and potential risk of print-out on the edgeband. Robatech’s FKW 60 applicator head applies the adhesive very precisely in the same quantity and quality. Remnants of glue and contamination are avoided.

Robatech systems are featuring

- Acurate application weight of adhesive

- Uniform coating of the adhesive

- Good temperature stability for the adhesive

- Always the same adhesive quality

- Less contamination

- Less glue consumption

- Quick change of plate thickness

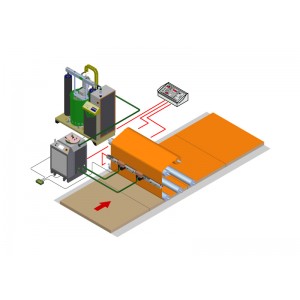

Melt On Demand - Technology

- Constant product quality thanks to a constant viscosity of the adhesive

- Uninterrupted production on topping up

- No PUR wasted

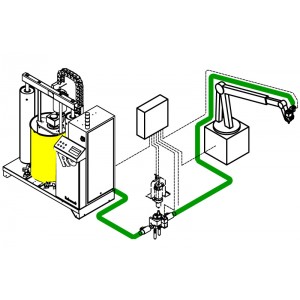

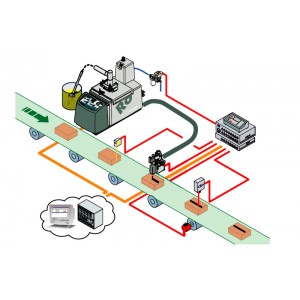

Suggested solution for Edge Banding

- Coating Heads FKW60

- RobaPur 4 MOD

- Concept-Serie

- Integrated pattern control AS-IK40/8

- Electronic Glue Pressure Control

- System Integration into the host machine:

RobaPAR, SNMP, Ethernet, CAN-Bus or Profibus

Leaflets