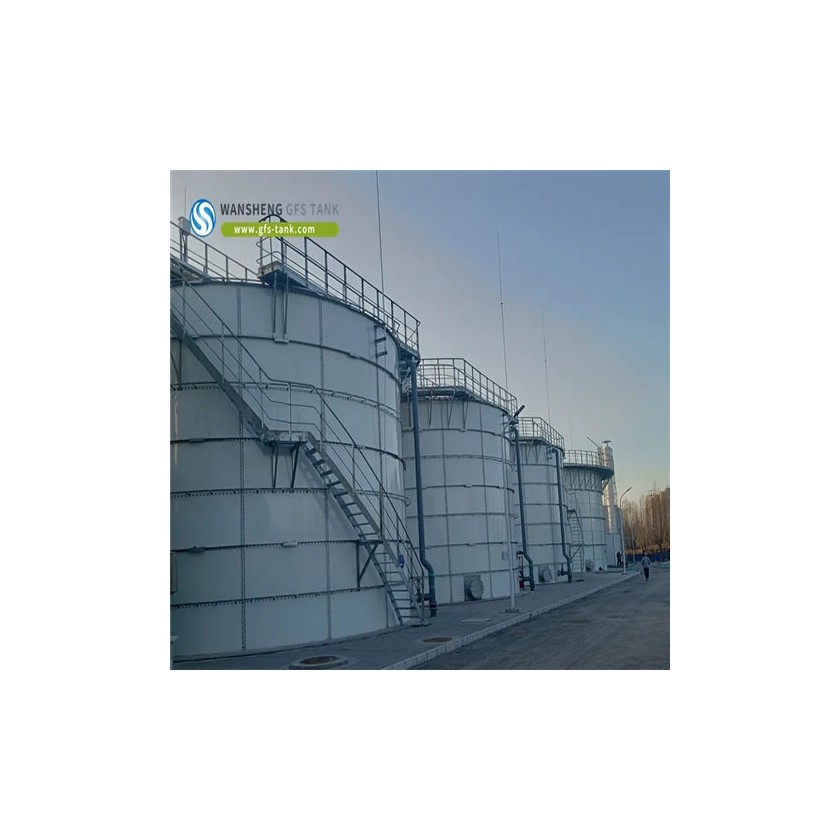

Glass-fused-to-steel Tank refer to glass-lined storage tanks, also known as some GFS storage tanks.

Glass is melted with steel to enhance its performance.

Fusion is important because it is single steel, and it is the same for the environment.

When the fusion of steel and glass is completed, the strength increases and the wear resistance decreases, as does the suitable pH value scaffold for alkaline solution.

Such ponds are generally considered to be one of the important components of environmental technologies, such as anaerobic digestion tanks, wastewater treatment and fireproof storage.

They are industrial water storage tanks.

The glass fused on the stainless steel tank panel is coated with glass enamel inside and outside.

The enamel has a strong, bright, smooth silicate coating.

Advantages of our Sludge Storage Tank

1. Short construction period and low cost.

2. Excellent corrosion resistance, service life> 30 years.

3. Easy to install, no need for large-scale installation equipment or very skilled worker.

4. The tank volume can be expanded according to your requirements.

5. Removable, relocated and reinstalled.

6. Exquisite appearance, the color of the tank can be customized.

7. Modular operation, on-site assembly.

8. Controllable quality, suitable for different climates.

9. Industrialized production, qualified in quality inspection.

10. Can produce any size, from 50m to 10000m for your choice

Main Parameters of Glass Coated Steel Tank

Item | Specs |

Coating Color | Standard color: dark blue and dark green,or customized |

Coating Thickness | 0.25~0.40mm |

Acid and alkali resistance | Standard coating:PH3~11,special coating:PH1~14 |

Elasticity | About 500KN/mm |

Life | ≥30years |

Holiday test | 1500v |

Adhesive force | 3450N/cm |

Hardness | 6.0(Mohs) |

Life | More than 30 years |