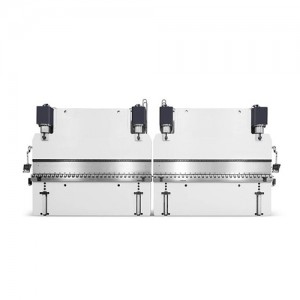

Integrated Precision – Single-platform laser machines combine cutting and processing in one unit, ensuring high accuracy and consistent results.

Improved Efficiency – Streamlined workflow reduces setup time and simplifies operation, boosting overall productivity.

Space-Saving Design – Compact, all-in-one structure saves factory floor space and reduces equipment costs.

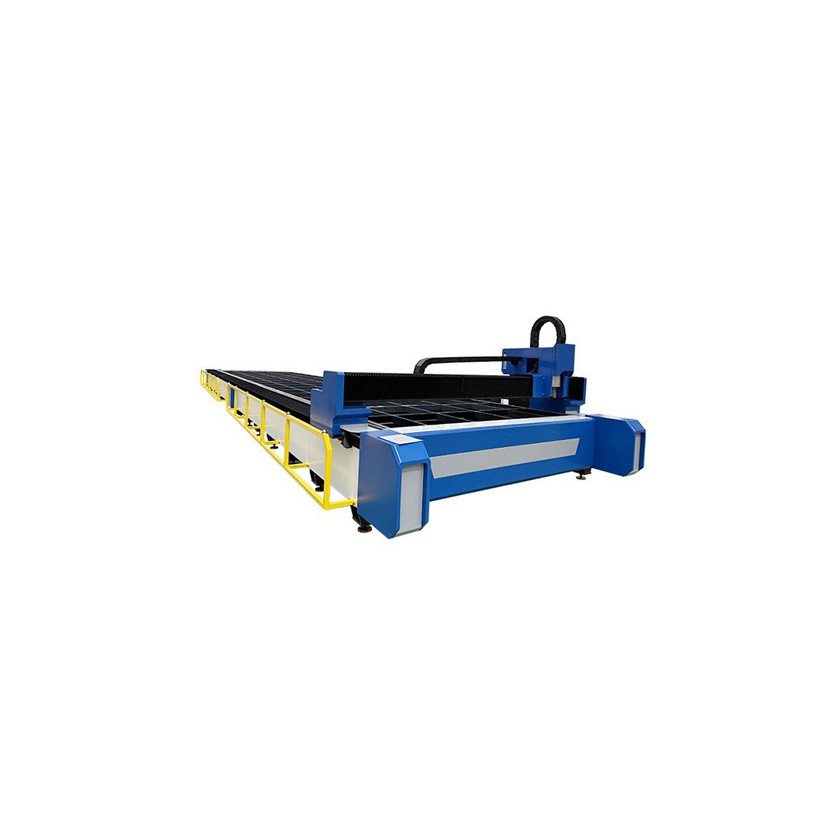

Mechanical Bed

1. High-Rigidity Welded Structure

The bed is made from high-strength steel with integrated welding, stress-relieved by high-temperature annealing. It offers excellent rigidity and vibration resistance, ensuring stable performance during high-speed cutting.

2. Long-Term Precision and Stability

Precision machining guarantees accurate mounting surfaces for key components. The structure remains stable and deformation-free even after years of heavy-duty use—maintaining cutting accuracy for over a decade.

3. Durable Design for Harsh Environments

Optimized by finite element analysis, the bed resists thermal deformation and structural fatigue. It performs reliably in high-power, high-temperature, and dusty industrial settings.

Beam

1. Lightweight design ensures fast acceleration and high cutting speed without sacrificing stability.

2. Rigid structural integrity minimizes deformation, ensuring precise motion during high-speed operation.

Achieve flawless cuts with our precision laser cutters—featuring CNC control, ultra fine beam quality, and automated material handling for high speed, low distortion fabrication.