Flexible Operation – The two machines can work in tandem for bending extra-long workpieces or function independently for separate tasks.

Improved Productivity – Dual usage increases production efficiency by adapting to different job sizes without the need for additional equipment.

Enhanced Value – Ideal for large-format fabrication, this setup delivers greater manufacturing value through higher capacity and operational versatility.

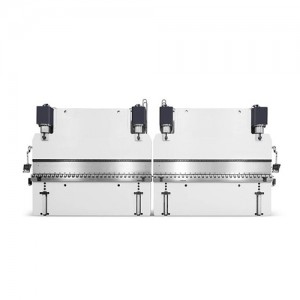

For extra-long metal bending, BOST Tandem Press Brake Machine synchronizes two independent brakes into one powerhouse system. This industrial solution transforms production for aerospace, energy, and heavy equipment manufacturers.

Top-Selling Product Parameter Table

Model | Parameter | ||

Tonnage (Each Machine) | 100T | 150T | 200T |

Working Length | 6m + 6m | 8m + 8m | 10m + 10m |

Max Bending Length | 12m | 16m | 20m |

Stroke | 300mm | 400mm | 500mm |

Accuracy | ±0.05mm | ±0.05mm | ±0.05mm |

Control System | DELEM DA-69 | CYBELEC DNC | BOST-CNC X8 |

Ram Speed | 15mm/s | 12mm/s | 10mm/s |

Power | 15kW | 22kW | 30kW |

BOST innovation replaces costly custom mega-presses by linking two CNC press brakes. This configuration handles extra-long workpieces (20+ meters) seamlessly while allowing independent operation for smaller tasks. Ideal for high-mix production, our Tandem Press Brake Machine delivers unmatched flexibility and 40% faster throughput.