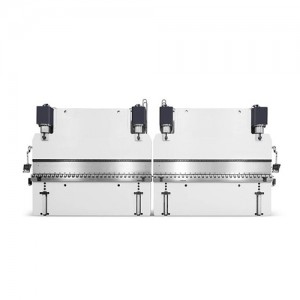

High Precision: Utilizing servo-hydraulic systems and CNC controls, these CNC Press Brake machines achieve bending tolerances as tight as ±0.01mm, ensuring consistent and accurate results.

Enhanced Efficiency: With programmable automation, they streamline complex bending tasks, reducing setup times and increasing production throughput.

Versatility: Capable of handling various materials and thicknesses, they accommodate diverse applications across industries like automotive, aerospace, and sheet metal fabrication.

CNC Controller

The controllers are sourced from European countries—Delem from the Netherlands, ESA from Italy, and Cybelec from Switzerland—ensuring quality and reliability.

Algorithms are advanced enough to optimize bending cycles and decrease setup times, thus boosting productivity, especially during batch processing tasks.

(Options: DELEM DA53T, DA58T, DA66T, DA69T, ESA s630 ,CYBELECK CT12,CT15 etc.)

Hydraulic System

1.The Hybrid system represents a cutting-edge servo drive solution for press brakes. Leveraging a brushless motor, this technology enables precise ram movement control while minimizing both oil usage and energy consumption.

Lower Energy Consumption

Clearly Reduced Cooling Effort

Higher Operation Speeds

Remarkable Noise Reduction

More Than 30% Oil Save

2.Rexroth hydraulic valves offer exceptional durability and high-pressure resistance, ensuring reliable performance under demanding conditions.

The machines equipped with these valves support multiple actions, such as rapid and slow descent, working speed bending, rapid return, and an emergency stop feature for enhanced operational flexibility and safety.

We are a China Press Brake Machine manufacturer. Our company was founded in 2002, and has more than 20 years of production experience. For more details please contact www.bostmachinery.com