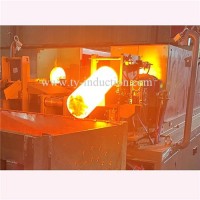

Induction Brazing Heater

Product Description

Induction brazing equipment is a type of machinery used for the process of brazing. Brazing is a method of joining two or more metal components by heating them to a temperature that is lower than their melting points, and then adding a filler metal, such as a brazing alloy, which melts and flows between the components to create a strong, permanent joint.

Induction brazing is a process of joining two metal components together using a brazing filler metal. It involves heating the metal components with an induction coil to a temperature above the melting point of the brazing filler metal, but below the melting point of the metal components being joined. The brazing filler metal is then melted and flowed between the metal components by capillary action, forming a strong and permanent bond.

The induction heating process used in induction brazing involves the use of an alternating magnetic field generated by the induction coil, which induces eddy currents in the metal components being joined. The resistance of these currents causes the metal to heat up rapidly and uniformly, without the need for a separate heating element.

Induction brazing equipment uses electromagnetic induction to generate heat in the metal components to be brazed. An alternating current is passed through a coil, which creates a magnetic field that induces eddy currents in the metal. These eddy currents create heat, which raises the temperature of the metal and melts the brazing alloy.

Induction brazing equipment can be used to braze a wide range of metals, including copper, brass, steel, stainless steel, and aluminum, and is commonly used in industries such as automotive manufacturing, aerospace, and electronics. Some of the advantages of induction brazing equipment include its ability to provide rapid, localized heating, precise temperature control, and high energy efficiency.