Aluminum coil coating is a kind of polyester coating coil. It has the characteristics of high weather resistance, which can effectively improve the anti-ultraviolet ability and prolong the service life of outdoor use.

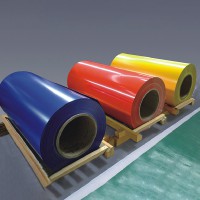

Painted Aluminium Coil

Painted aluminium coil is a color coating treatment on aluminum coil. Commonly fluorocarbon color coated aluminum and polyester color coated aluminum are widely used in aluminum composite panels, aluminum veneer, aluminum honeycomb panels and so on. Aluminum ceilings, roof surfaces, leftovers, cans and electronic products. Its performance is very stable and not easy to corrode. After special treatment, the surface can reach 30 years of quality assurance. The weight per unit volume is the lightest among metal materials.

painted aluminium coil is treated with various colorful paint coatings on the surface of aluminum coils after washing, chromium penetration, roller coating, baking and other processes.

Coatings applied to Painted aluminium coil and sheets serve a number of purposes, including:

Protecting the aluminum from corrosion and other types of damage

Improving the appearance of the aluminum by providing a uniform, smooth finish

Enhancing the performance of the aluminum in certain applications, such as in the construction or automotive industries

There are several different types of coatings that can be applied to painted aluminium coil, including:

PVDF (polyvinylidene fluoride) coatings: These coatings provide excellent weathering resistance and are commonly used in architectural and construction applications.

Powder coatings: These coatings are made from dry, finely ground resin and are applied to the aluminum using heat. They are known for their excellent corrosion resistance and durability.

Anodized coatings: These coatings are formed by an electrolytic process that creates a thin, oxide layer on the surface of the aluminum. Anodized coatings are known for their excellent corrosion resistance and durability.

Organic coatings: These coatings are made from a variety of organic materials, such as paints, enamels, or lacquers, and are applied to the aluminum using a variety of techniques, such as roll coating or spray coating. Organic coatings are commonly used for decorative or aesthetic purposes.

In summary, painted aluminium coil is the process of applying a protective layer or coating to aluminum coils or sheets to protect the aluminum and improve its performance in certain applications. There are several different types of coatings that can be applied to aluminum, including PVDF, powder, anodized, and organic coatings.

Advantages of Painted Aluminium Coil:

1. Light texture, easier to form

2. Corrosion resistance Because its surface has a dense oxide film, it has strong adhesion, anti-oxidation, acid resistance, alkali resistance, corrosion resistance, corrosion resistance, and UV resistance.

3. Good temperature resistance, the melting point of aluminum is 660 degrees, and the general temperature does not reach its melting point

4. The board has extremely high strength and can be cut, slit, balanced, drilled, joined, fixed and compressed at the edges.

Applications

● Building facades

● Curtain wall and shading elements

● Roofing

● Roller blinds

● Composite walls and partitions

● Ceiling panels

● Laminate or sandwich panels

● Decorative panels

● Billboards

The painted aluminium coil performance

PVDF & FEVE & HDPE coated aluminum coil performance | ||||||

Item | Testing | Standard | Standard requirement | PVDF | FEVE | HDPE |

1 | Color | ECCA T3 | Using range | Matt and dark colors | All colors | All colors |

2 | Gloss | ECCA T2 | Max. gloss degree | 35 | 85 | 90 |

Min. gloss degree | 15 | 50 | 20 | |||

3 | Coating Thickness | ECCA T1 | 2 layers coating Min.23µm | ≥25µm | ≥25µm | ≥25µm |

3 layers coating Min. 30µm | ≥34µm | according to requirements | according to requirements | |||

4 | Pencil Hardness | ECCA T4 | ≥HB | HB | H | H |

5 | T-bend | ASTM D4145 | Aluminum thickness≥0.50mm | 90 degrees no crack | / | 90 degrees no crack |

Aluminum thickness<0.50mm | 2T | 2T | 2T | |||

6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 | Grade 0 | Grade 0 |

7 | Impact Resistance | ASTM D2794 | ≥50kg.cm | ≥50kg.cm | ≥50kg.cm | ≥50kg.cm |

8 | Boil Resistance | GB/T17748 | 2 hours no change | 4 hours no change | 2 hours no change | 2 hours no change |

9 | Solvent Resistance | ASTM D2248 | 200 times no change | 200 times no change | 200 times no change | 200 times no change |

10 | Acidity Resistance | ASTM D1308 | 5%HCL 24h, no change | 5%HCL 24h, no change | no change | 2%HCL 24h, no change |

11 | Alkalescence Resistance | ASTM D1308 | 5%NaOH 24h,△E≤2.0 | 5%NaOH 24h,△E≤2.0 | 5%NaOH 24h, △E≤2.0 | saturated Ca(OH)2 24 hours△E≤2.0 |

12 | Nitric acid Resistance | AAMA620 | △E≤5.0 | △E≤5.0 | △E≤5.0, slight blister | △E≤5.0, slight blister |

13 | Oil Resistance | ASTM D1308 | 20#Engine oil 24 hours no change | 20#Engine oil 24 hours no change | 20#Engine oil 24 hours no change | no change |

14 | Salt Resistance | ASTM B117 | 4000hours no less than grade 1 | 4000hours no less than grade 1 | 4000hours no less than grade 1 | 2000 hours corrosion edge≤2mm |

15 | Abrasion Resistance | ASTM D968 | ≥5L/µm | ≥5L/µm | Waiting for the third-party testing | Waiting for the third-party testing |

16 | Dirt Resistance | GB/T9780 | ≤5% | <5% | Waiting for the third-party testing | Waiting for the third-party testing |

17 | Color retention | GB/T16259 | 4000hrs,△E≤4.0 | 4000hrs,△E≤4.0 | 2000 hours△E≤4.0 | 2000 hours△E≤4.0 |

18 | Gloss weaken level | 4000hours no less than grade 2 | 4000hours no less than grade 2 | 2000h, no less than grade 2 | 2000h, no less than grade 2 | |

19 | Chalk resistance | 4000 hours no change | 4000 hours no change(no less than grade 2) | 2000hours, no less than grade 2 | 2000hours, no less than grade 2 | |

20 | Fluoride resin percentage | 70% | ≥95% | none | ||

21 | Guarantee for exterior using | GB/T16259 | 10-15 years in different colors | 10-15 years in different colors | 7-8 years in different colors | |

About manufacturer

As one of the most professional coated aluminum coil manufacturers and suppliers in China, with our experience and good management here, you will find the right coated aluminum coil with us, we are your reliable partner.

When you contact us, please provide your detailed requirements. That will help us give you a valid quotation.