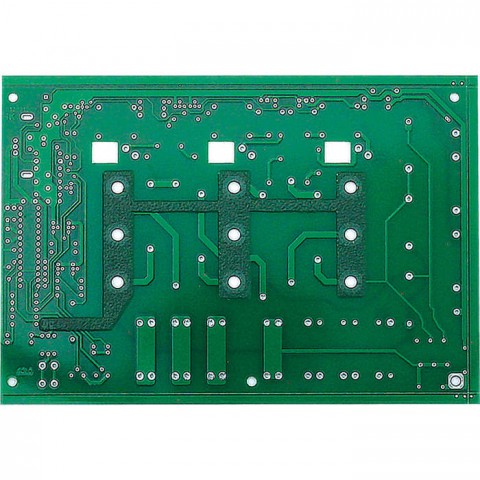

Lead Free HASL PCB

Product Description

HASL is the predominant surface finish used in the industry. The process consists of immersing circuit boards in a molten pot of a tin/lead alloy and then removing the excess solder by using 'air knives', which blow hot air across the surface of the board.

One of the unintended benefits of the HASL process is that it will expose the Printed Circuit Board to temperatures up to 265°C which will identify any potential decontamination issues well before any expensive components are attached to the board.

Application area: Security | Product feature: Peelable S/M |

Layer: 2 | Surface treatment: Lead Free HASL |

Material: FR4 | Line width/Line space: 0.325/0.305mm |

Thickness: 1.6mm | Min hole φ: 0.75mm |

Choosing a PCB surface finish that works best for you and your process while still keeping the environment safe is has become a much more practical solution.

We are Printed Circuit Board Supplier, more please click here.