Reinforcing Concrete Mesh is a multi-purpose steel reinforcing mesh, which is suitable for the use of more structural building slabs and footing. It consisted of a series of high-strength wires welded together to form a square or rectangular grids fabric.

The application of Reinforcing Concrete Mesh

1. Prefabricated cages

2. Precast building components

3. Retaining wall

4. Reinforcement of slab

5. Precast products such as drainage, box culvert, RC U-drain, pipe culvert, and other precase concrete panels industries.

Features of our concrete reinforcing mesh

The welded wire fabric makes them easier to work on.

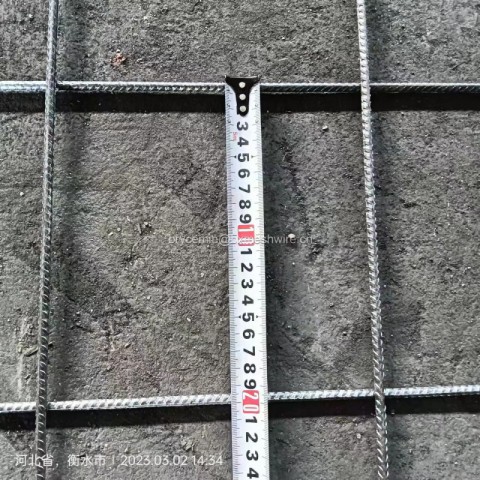

There are different diameters of steel reinforcing mesh each suited for a particular application.

There are different designs of steel reinforcing mesh from bent and rolls to flat sheets.

As per BS 4482 standards and codes, the stainless steel wire used in the manufacture of the

steel reinforcing mesh has a 510MPa tensile strength and 485MPa minimum proof stress.

The steel reinforcing mesh is rigid making it possible for you to control concrete cover during

construction.

Manufacturers produce steel reinforcing mesh under SANS1024 Standard Specifications.

The steel bars stay intact whenever immersed in concrete because they are carefully welded

in mats.

You don’t have to apply additional surface treatment to the steel reinforcing mesh before

use.

Less field labor needed when making reinforced concrete slabs using this mesh thus

drastically speeding up the construction process.

The mesh is easy to load and unload, and easy to handle at the working site.

Properly mixed concrete is poured into the mesh and then given time to dry out. The

concrete, as it continues to dry out, it grips the steel bars tightly creating a bond stress

between these two materials. This bond stress is essential because it reduces bending and

makes reinforced concrete slabs stronger.

https://www.bxmeshwire.cn/