Buy Vacuum Molding Ceramic Fiber Board from Super Refractory Fiber Manufacturer, smooth surface, accurate size & density, high resistance to press.

Description:

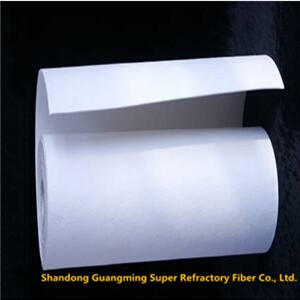

Super ceramic fiber board is made from super ceramic blown fiber bulk

with inorganic and suitable organic binders through vacuum molding and

microwave furnace drying and formation. In the process of heating

application, the organic binder will be volatilized at the temperature

250-350℃, after volatilization, the board is pure white.

Characteristics:

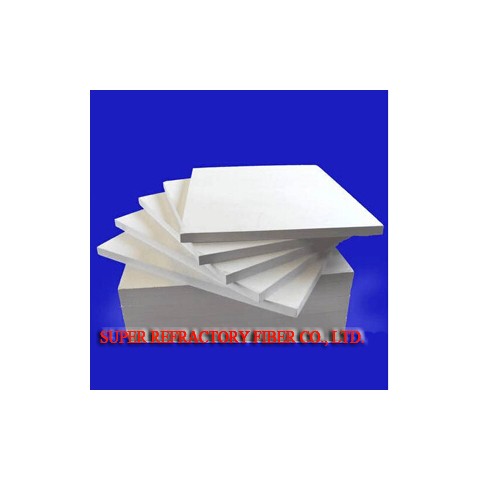

* Smooth surface, accurate size, even density.

* High resistance to press and wind corrosion.

* Excellent thermal and chemical stability.

* Excellent tenacity, easy to cut.

* Low heat storage, low thermal conductivity, low shrinkage, excellent insulation effect.

* Good erosion resistance.

* Easy application, can be used in direct contact with flame.

* The classification temperature: 1050℃, 1260℃, 1360℃, 1450℃.

Applications:

* Back-up lining material of high temperature industry furnace.

* Hot-face lining of ceramic kiln, heat treatment furnace and other industry kilns.

* Back-up insulation for castable, brick and monolithic refractory.

* Barrier again heat or flame.

Company

Company