Major infrastructure use of Evcco HFT conduit

for extensive Sydney tunnel project

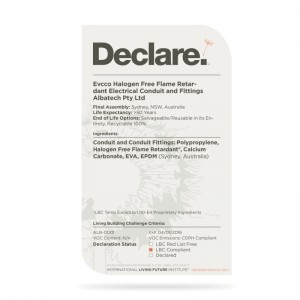

Evcco, an Australian manufactured electrical and safety conduit that is many times lighter and easier to install than metal conduit has achieved another of its major infrastructure uses. Evcco’s HFT polymer plastic conduit with halogen free flame retardant properties has been selected by the United Group for the Epping to Chatswood Rail Line in Sydney.

Evcco’s HFT polymer plastic conduit with halogen free flame retardant properties has been selected by the United Group for the Epping to Chatswood Rail Line in Sydney. about 2.5 kilometres of the new product is being used to carry electrical services from one side of the tunnels to the other, with the tough flexible electrical conduit pipe conforming to the semi-circular arc of the tunnel crown.

“The difficulty with metal pipe in tunnels is that it has to be bent to conform with the radius, presenting installation difficulties as well as OH&S issues where personnel have to cope with the greater weight of the material being maneuvered. Naturally there are also corrosion issues where steel is used, particularly in aggressive environments,” says Mr John McNab, Managing Director of Evcco.

Evcco introduced its Halogen Free Flame Retardant (HFFR) polymer electrical conduit pipe and fittings as an alternative to imported systems typically costing more than twice as much. In addition to carrying electrical cabling, it can be used within safety equipment such as aspiration systems and air sampling systems that are used to protect against smoke and toxicity.

Now available in diameters from 20mm – 110mm in response to demand in Australia, the Pacific and Asia, the electrical conduit pipe and fittings are especially formulated to meet high fire safety requirements in surface and sub-surface applications. Two sizes are involved in the rail link project:

- 90mm outside diameter (80mm inside diameter) 1.34km

- 63mm outside diameter (55mm inside diameter) 1.19km

Producing no corrosive or toxic fumes in the event of a fire, the Low Smoke Zero Halogen (LSZH)range of polymer conduit is designed for use in situations where there are high concentrations of people, high concentrations of assets or risk of high costs due to production interruption.

Applications include advanced technology industrial plants, mines, tunnels, airports, subway systems, power plants, oil refineries, lifts, emergency plants, ships, aircraft, trains, computer and telecommunication installations. It can also be used in hospitals, schools, hotels, museums, theatres, shopping centres and conference centres.

Mr McNab says the new conduit is the result of an extensive research and development programme designed to overcome hurdles in producing halogen free flame retardant pipe and conduit without degrading their overall performance, including impact resistance or pressure capability. The HFT electrical conduit is complemented by both standard HFT super glue polymer plastic pipe fittings or high performance HFT IP67 electrical conduit fittings

“What is particularly important in applications such as the Epping to Chatswood Rail Line tunnel is ease of use in situations that can sometimes offer limited access within fairly restricted production schedules. With this system you don’t have to bring in a variety of trades to handle it, the whole system is designed for radically simplified erection, disassembly and recycling within a fraction of the time taken to construct and change traditional metal alternative conduits.

“Weighing just one eighth the weight of galvanized steel, for example, it can be easily installed with far fewer OH&S issues than heavier materials. Also, its flexibility enables it to confirm readily to irregular contours, such as those encountered in tunnels and trenches. This flexibility and ease of installation can produce considerable savings,” said Mr McNab.

Properties of the new HFT range include: