GK9920,GK990 Series superfine pulverizer is mainly used in metallurgy, chemical industry, construction, pharmaceuticals, ceramics, electronics, military and other industries. For deep processing non-flammable, non-explosive mineral materials whose Mohs hardness and humidity is under 9 and 6% respectively, such as Talc, feldspar, zeolite, Calcite, barite, pyrophyllite, dolomite, Phosphate rock, wollastonite, coal, kaolin, bentonite, bauxite, titanium dioxide, ferrosilicon, gypsum, mica, quartz, corundum, zircon sand, emery and so on.

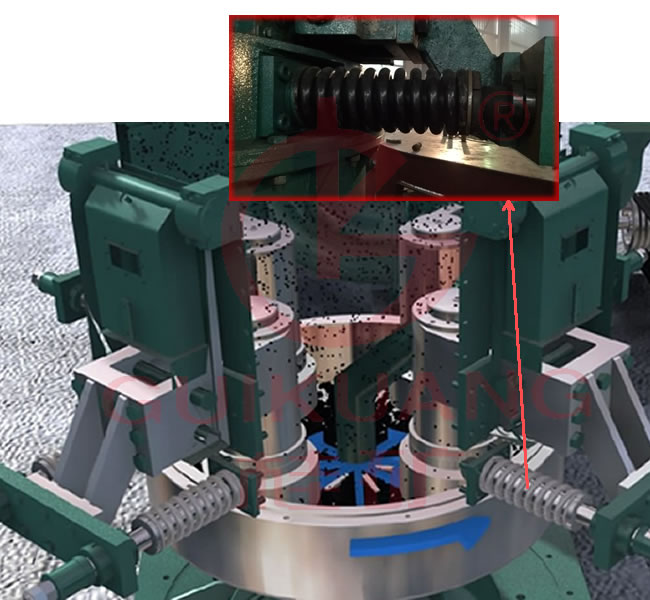

◆ Lower Iron Content & Keep Material Color

◆ Lower Maintenance Cost

◆ Strong Grinding Force

◆ Super-fine Product

◆ High Capacity & Low Consumption

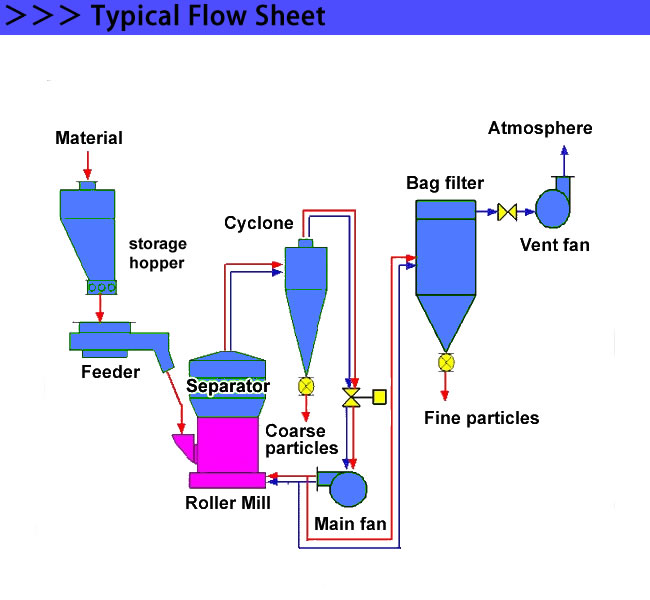

Working Process:

Accessory equipment |

|

|

Rotary feeder |

Used to feed materials. |

|

Whizzer separator |

Used to classify coarse particles. |

|

Cyclone collector |

Used to collect products. |

|

Main fan |

Used to transport products and circulate air. |

|

Vent fan |

Used to exhaust surplus air. |

|

Bag filter |

Used to support collection of products. |

|

Ducts |

Used to transport products and circulate air. |

Model Optional:

| Model | Roller Size(OD*Height) | Ring Inner Diameter | Max Feed Size | Product Size | Central Shaft Rotate Speed | Capacity | Total Motor Power | Total Weight | Moisture of Feeding Size | Moh's Hardness | Overall Dimension(L*W*H) |

| GK1720 | Φ510*300 mm | Φ1720 mm | 30 mm | 80~600 mesh | 88 r/min | 5500~25000kg/h | 375 kw | 46 t | ≤7% | ≤7 | 12500*12250*10400 mm |

| GK1500 | Φ450*300 mm | Φ1500 mm | 30 mm | 80~600 mesh | 108 r/min | 2500~24000 kg/h | 282 kw | 32 t | ≤7% | ≤7 | ************ |

| GK1280 | Φ370*240 mm | Φ1280 mm | 20 mm |

80~600 mesh |

150 r/min | 2000~15000 kg/h | 133.5 kw | 18 t | ≤7% | ≤7 | 8500*7500*8200 mm |

| 5R4128 | Φ410*280 mm | Φ 1270 mm | 30 mm | 80~600 mesh | 112 r/min | 2200~20000 kg/h | 220.5 kw | 29.6 t | ≤7% | ≤7 | 10100*9300*8330 mm |

| 5R4119 | Φ410*190 mm | Φ 1270 mm | 30 mm | 80~325 mehs | 105 r/min | 2000~6500 kg/h | 156 kw | 28 t | ≤7% | ≤7 | 9575*7652*15510 mm |

| 4R3220 | Φ320*200 mm | Φ 970 mm | 20 mm | 80~600 mesh | 150 r/min | 1000~7000 kg/h | 97.5 kw | 14.7 t | ≤7% | ≤7 | 7860*5990*11880 mm |

| 4R3216 |

Φ320*160 mm |

Φ 970 mm | 20 mm | 80~325 mesh | 145 r/min | 1000~3000 kg/h | 81.2 kw | 14 t | ≤7% | ≤7 | 7860*5990*11880 mm |

| 2R2613 | Φ 260*130 mm | Φ 760 mm | 15 mm | 60~325 mesh | 180 r/min |

300~3000 kg/h |

31.7 kw | 4.3 t | ≤7% | ≤7 | 4990*3575*6440 mm |

| GK9920 | Φ 365*240 mm | Φ1250 mm | 10 mm | 600~1500 mesh | 116 r/min | 1200~2500 kg/h | 140.5 kw | 28.5 t | ≤7% | ≤7 | 5730*7070*9270 mm |