Raymond mill is also called Raymond roller mill, Raymond pulverizer and Raymond grinder. This powder grinding mill is mainly used in powder making plant or powder grinder line.

Economical, reliable, maintenance-free, energy-efficient pulverizing system available by incorporating the latest developments

Advantages of Raymond Mill:

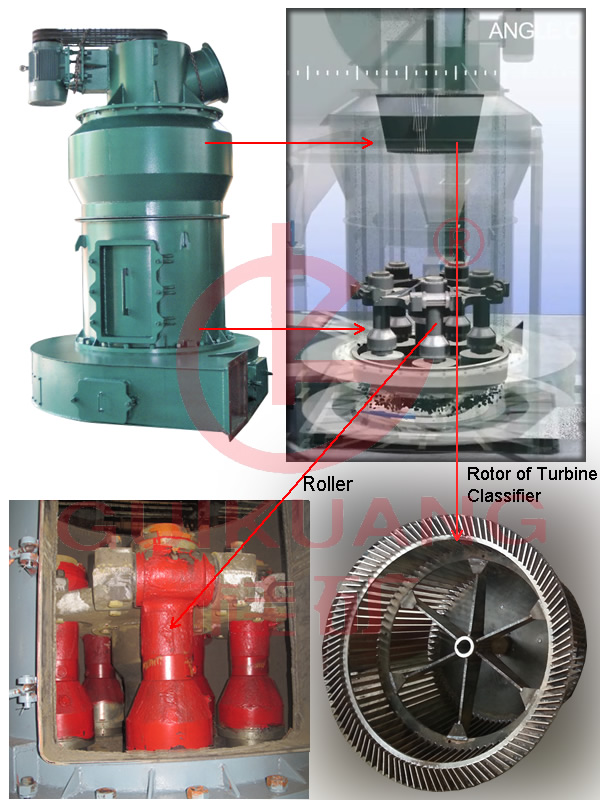

1. With three-dimensional structure, small floor space, and complete set of equipment, Raymond mill is an independent system from oversized materials to finished powder.

2. The fineness of finished products is uniform. The sieving rate reaches 99 %, which is difficult for other mill equipment.

3. The gearing of Raymond mill adopts sealed gear box and band pulley, which transmits smoothly and operates reliably.

4. The important parts are made of high quality steel. Wear parts are made of high wear-resistant materials. The overall machine has strong wear resistance and operates reliably.

5. The electric system of Raymond mill adopts centralized control. Unmanned operation of workshop becomes a reality.

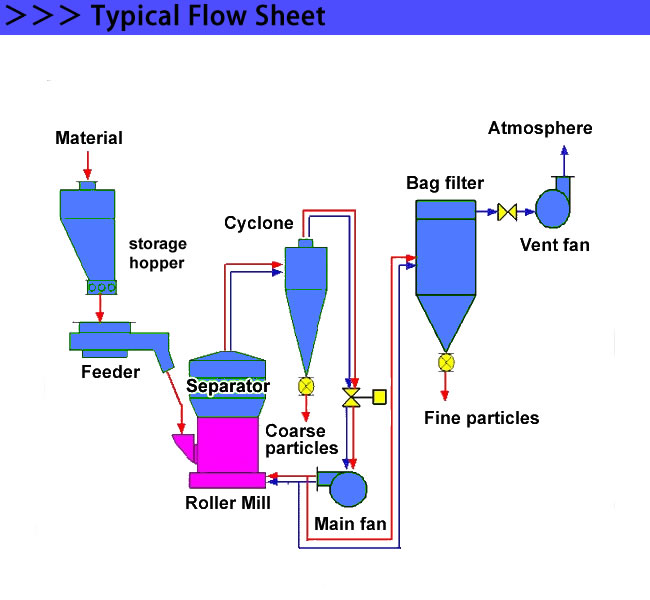

Working Process:

Accessory equipment |

|

|

Rotary feeder |

Used to feed materials. |

|

Whizzer separator |

Used to classify coarse particles. |

|

Cyclone collector |

Used to collect products. |

|

Main fan |

Used to transport products and circulate air. |

|

Vent fan |

Used to exhaust surplus air. |

|

Bag filter |

Used to support collection of products. |

|

Ducts |

Used to transport products and circulate air. |

Model Optional:

| Model | Roller Size(OD*Height) | Ring Inner Diameter | Max Feed Size | Product Size | Central Shaft Rotate Speed | Capacity | Total Motor Power | Total Weight | Moisture of Feeding Size | Moh's Hardness | Overall Dimension(L*W*H) |

| GK1720 | Φ510*300 mm | Φ1720 mm | 30 mm | 80~600 mesh | 88 r/min | 5500~25000kg/h | 375 kw | 46 t | ≤7% | ≤7 | 12500*12250*10400 mm |

| GK1500 | Φ450*300 mm | Φ1500 mm | 30 mm | 80~600 mesh | 108 r/min | 2500~24000 kg/h | 282 kw | 32 t | ≤7% | ≤7 | ************ |

| GK1280 | Φ370*240 mm | Φ1280 mm | 20 mm |

80~600 mesh |

150 r/min | 2000~15000 kg/h | 133.5 kw | 18 t | ≤7% | ≤7 | 8500*7500*8200 mm |

| 5R4128 | Φ410*280 mm | Φ 1270 mm | 30 mm | 80~600 mesh | 112 r/min | 2200~20000 kg/h | 220.5 kw | 29.6 t | ≤7% | ≤7 | 10100*9300*8330 mm |

| 5R4119 | Φ410*190 mm | Φ 1270 mm | 30 mm | 80~325 mehs | 105 r/min | 2000~6500 kg/h | 156 kw | 28 t | ≤7% | ≤7 | 9575*7652*15510 mm |

| 4R3220 | Φ320*200 mm | Φ 970 mm | 20 mm | 80~600 mesh | 150 r/min | 1000~7000 kg/h | 97.5 kw | 14.7 t | ≤7% | ≤7 | 7860*5990*11880 mm |

| 4R3216 |

Φ320*160 mm |

Φ 970 mm | 20 mm | 80~325 mesh | 145 r/min | 1000~3000 kg/h | 81.2 kw | 14 t | ≤7% | ≤7 | 7860*5990*11880 mm |

| 2R2613 | Φ 260*130 mm | Φ 760 mm | 15 mm | 60~325 mesh | 180 r/min |

300~3000 kg/h |

31.7 kw | 4.3 t | ≤7% | ≤7 | 4990*3575*6440 mm |

| GK9920 | Φ 365*240 mm | Φ1250 mm | 10 mm | 600~1500 mesh | 116 r/min | 1200~2500 kg/h | 140.5 kw | 28.5 t | ≤7% | ≤7 | 5730*7070*9270 mm |

Company

Company