Graphene nanoplatelets represent a new class of carbon nanoparticles which multifunctional properties. UG Graphene nanoplatelets has a very thin but wide aspect ratio with an average thickness of 1.46 – 3.54 nanometers are offered in varyingsize up to 30-100 microns. Because of their unique nanoscale size shape and material composition, UG Graphene Nanoplatelets can be used to improve the properties of wide range of polymeric materials, including thermoplastic and thermo set composites natural or synthetic rubber, thermoplastic elastomers, adhesives, paints and coatings.

With UG Graphene Nanoplatelets, you can:-

◆Increase thermal conductivity and stability

◆Increase electrical conductivity

◆Improve barrier properties

◆Reduce component mass while maintaining or improving properties

◆Increase stiffness

◆Increase toughness (impact strength)

◆Improve appearance, including scratch and mar resistance

◆Increase flame retardanc

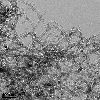

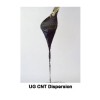

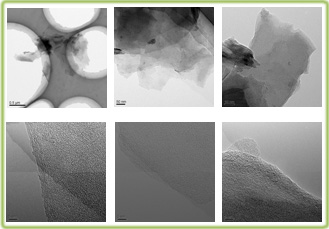

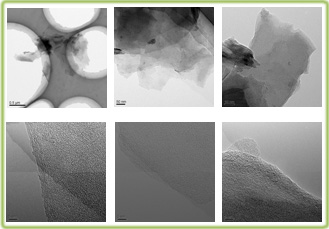

GNP SEM & TEM Pictures

Enhancing Thermal Conductivity

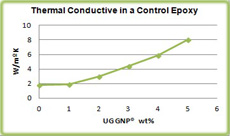

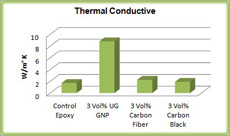

Graphene Nanoplateles are both thermally and electrically conductive, Unlike nanotubes or carbon fibers, however, the UG GNP provides lower thermal contact resistance at lower loading levels, resulting in higher thermal conductivity vs. other carbon particles or fibers. Graphene nanoplateletscan be used to lower the coefficient of thermal expansion(CTE) of most polymers and increase ultimate use temperature (T) values. Dimensional stability and operating temperature range are also increased, making polymers modified with UG Graphene Nanoplateles excellent for dimensionally critical parts in thermally demanding environments

GNP SEM & TEM Pictures

Enhancing Thermal Conductivity

Graphene Nanoplateles are both thermally and electrically conductive, Unlike nanotubes or carbon fibers, however, the UG GNP provides lower thermal contact resistance at lower loading levels, resulting in higher thermal conductivity vs. other carbon particles or fibers. Graphene nanoplateletscan be used to lower the coefficient of thermal expansion(CTE) of most polymers and increase ultimate use temperature (T) values. Dimensional stability and operating temperature range are also increased, making polymers modified with UG Graphene Nanoplateles excellent for dimensionally critical parts in thermally demanding environments

Increasing Electrical Conductivity

The graphene sheets that form these nanoplatelets are also highly conductive and create an effective conducting network at low loading levels in most polymeric materials. ESD and EMI/RFI shielding capabilities are typically achieved at loading levels of 2 - 3 wt% in thermoset resins and 5 -7 wt% in thermoplastics.

Unlike many conductive additives, though, these nanoplatelets do not negatively affect the base resin's mechanical and aesthetic properties, nor are they abrasive to tooling as metal flake and fiber can be.

Please contact us to discuss your specific needs or request more information.