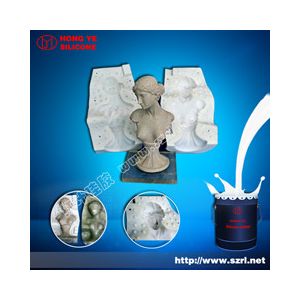

Platinum cure silicone rubber is a kind of FDA grade silicone, generally named two components silicone rubber with translucent appearance, Part A and part B mixing in 1:1. It’s suitable for molds making application.

Platinum cure silicone rubber applications

Platinum cure silicone rubber mainly used for making concrete stones, wax molds, PU molds, resin molds, gypsum casting, candle molding and chocolate , candy and any other food product molds making.

Platinum cure silicone rubber advantages

1) Non- shrinkage (less than 0.1%)

2) High tensile and tear strength with high copy times

3) Exceptional fluidity and good operability (mixing ratio at 1:1)

4) High temperature resistant in 250 Centigrade

Platinum cure silicone rubber operation instructions

Step One: Take 100g of part A and 100g of part B and mix in 1:1 and mix the two parts evenly.

Step Two: vacuum pumping

Without exception, this step takes less than 10 minutes.

Note: The time for vacuum-pumping should be less than 3-5 minutes. Otherwise, once the silicone rubber has cross-

Step Three: Pouring the mixture into the

Shelf life for platinum cured silicone rubber

8~10months, when stored in a dry & cool place under the room temperature 25.

Packing for platinum cured silicone rubber

20kg/drum for part A+ 20kg/drum for part B in one set

200 kg/drum for part A+ 200kg/drum for part B in one set

For more information , please feel free to contact Ms Phoebe

office no. :0086-0755-89212380

Mob:86-13510160545

Skype: siliconerubberphoebe

Email : siliconehyj(at)gmail(dot)com

Welcome to our website www(dot)szrl(dot)net

Company

Company