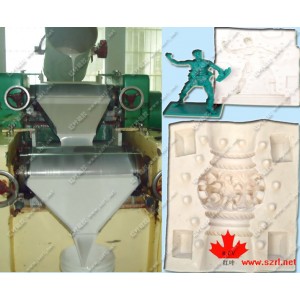

Manual molding silicone rubber

1. Good elasticity

2. Non-deformation

3. Heat resistance

4. Low shrinkage

a. Applications of Manual Molding Silicone Rubber

Manual Molding Silicone Rubber is mainly used for model design of manual mold, PVC plastic molds, cement products, low melting point alloy molds, alloy toys, plastic toys, electronics, handicrafts, stationery, large-scale sculpture, reproduction of cultural relic, shoe sole molds, pad printing allocation, Electronic equipment antivibration, etc.

b. Model Codes of Manual Molding Silicone Rubber

HY-528# is applicable to make molds of smaller products and the production will be 2-3 pieces.

HY-540#, compared to other two types, for its moderate hardness and better quality & performance, its production will be 20-30 pieces.

HY-570# is applicable to large size products duplications and Electronic equipment antivibration.

c. Operation Instructions for Manual Molding Silicone Rubber

RTV-2 Manual Molding Silicone Rubber is a flowable liquid, and the quality has nothing to do with the color. It consists of two component. Part A is a flowable liquid silicone rubber, part B is the curing agent. Firstly, after your previous work of dealing with the original model, take some liquid silicone rubber , add 2%-3% curing agent of the amount of silicon, and mix them evenly. Then after vacuum-pumping the mixture, you can pour it into the mold frame . The silicone mold will cured in 2-3 hours.

Note: The time for vacuum-pumping should be less than 3—5 mins ,otherwise, once the silicone rubber has cross-link reaction during vacuumizing, it will not be operated.

FAQ of manual molding silicone rubber

How to prevent silicone manual molds getting sticky?

The main reason for this problem is that you do not handle the products or original molds well, then you should deal with the original mold or products carefully before molding. Such as for the products with a complicated pattern or a unsmoothed surface, you should polish and clean the products after which it will be molded ,then spray the release agent. Normally, the release agent can be Vaseline , detergent. liquid wax Etc. In practical process, you can bush different release agent according to different material.

The second reason is that the operator pour the silicone into the mold when the mixture is mixed evenly, then the finish silicone mold will not cure and dry entirely.

Place of Origin Guangdong China

Brand Name HY silicone rubber

Shipping Terms:shenzhen port / by sea

Minimum Order Quantity: 200 Kilogram

Packaging Details: 25kg/drum and 200kg/drum

Delivery Time: within 3 days after payment confirmed in our bank.

Payment Terms: L/C,T/T

Supply Ability: 8 Ton per Day

Certifications:RoHS.MSDS.SGS ISO9001:2000

Further information on Manual Molding Silicone Rubber is available. Please feel free to contact Kaimi.

SHENZHEN HONG YE JIE TECHNOLOGY CO., LTD

Website: www(at)szrl(dot)net

ADD: Liulian Shibi industrial, Pingdi town, Longgang district, Shenzhen, China

Tel: 0086-0755-89948294

Mobile: 0086-18938867528

Fax: 0086-755-89948030

E-mail: hyju(at)szrl(dot)net

E-mail: hyju(at)szrl(dot)net

Company

Company