Our plastic trays are produced using vaccum forming or pressure forming methods. This Process involved heating of plastic sheets, forming sheets into shape, and trimming into required dimensions.

Trays can be designed for best fit of your products, it may comes with dividers, lid cover, stacking and locking features.

Blister-shell and Clam-shell type of packaging is best for display purpose.

Packaging trays can be used to pack electronic components, household items, use as food trays, and displays trays.

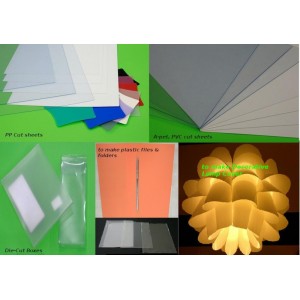

A wide range of plastic materials being used to make these type of trays, they areHIPS, A-pet, PVC, PP, HDPE. OPS, ABS.

Thickness is ranging from 0.18mm to 2.0mm

Food Contact Grade of materials are used for food packing applications.

Anti-static or Conductive trays can also be made using vacuum forming method, these trays are suitable to pack sensitive electronic components, and to meet ESD/cleanroom requirements.

Speciality materials could be arranged upon request.

Company

Company