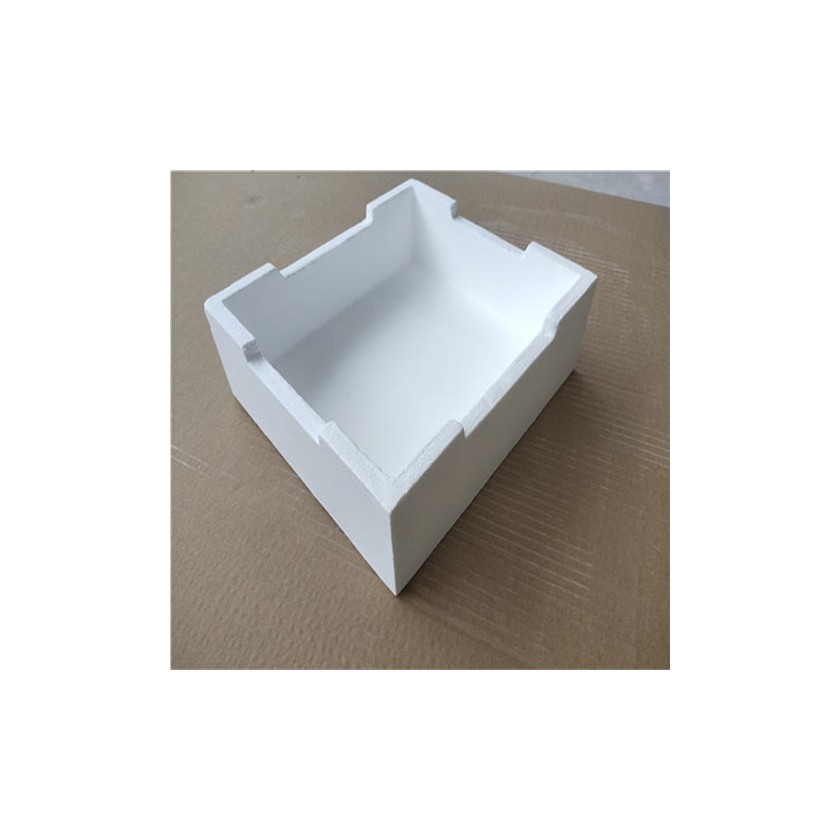

We specialize in providing High Purity Quartz Square Sagger tailored to meet your specific requirements. Our custom solutions are designed for high-temperature applications in industries such as electronics, ceramics, metallurgy, and laboratory research.

Advantages

1. High purity and high temperature resistance: Quartz sagger has high purity and can withstand high temperature environment. Its heat resistance temperature can reach 1500℃, which is suitable for use at high temperature without deformation or cracking.

2. Chemical stability and thermal stability: Quartz sagger has good chemical stability and thermal stability, can remain stable at high temperature, is not easy to react chemically with other substances, and has good thermal shock stability, and can be used under rapid cooling and heating conditions without cracking.

3. Good thermal insulation performance: Quartz sagger has excellent thermal insulation performance, which can effectively reduce heat loss and save energy.

4. Large size and high precision: Quartz sagger has large size and high precision, which can ensure the stability and consistency of the product.

5. Environmental protection and safety: Quartz sagger is environmentally friendly and safe, easy to clean and maintain, and has a long service life. It can be used for a long time without being easily damaged.

6. Good thermal conductivity: Quartz sagger has good thermal conductivity, can quickly transfer heat, ensure the uniform heating of the product at high temperature, and improve the glaze brightness and quality of the product.

7. Reasonable shape and various sizes: The shape of quartz sagger is reasonable and the size is various, which can optimize the volume utilization rate and facilitate the loading of blanks and kilns.

8. Increase the firing capacity and yield rate: Using quartz sagger to fire ceramics can increase the firing capacity, reduce the adhesion of products, and improve the yield rate.