Hooklift ydraulic system

It is composed of hydraulic gear pump, multi-way valve, hydraulic oil storage tank of oil cylinder, etc., and provides hydraulic dynamic force for the pulling arm mechanism through the system.

Hooklift control system

Through the multi-way valve handle, electronic control unit, controller to control the corresponding hydraulic actuator work, the garbage truck operation required action requirements.

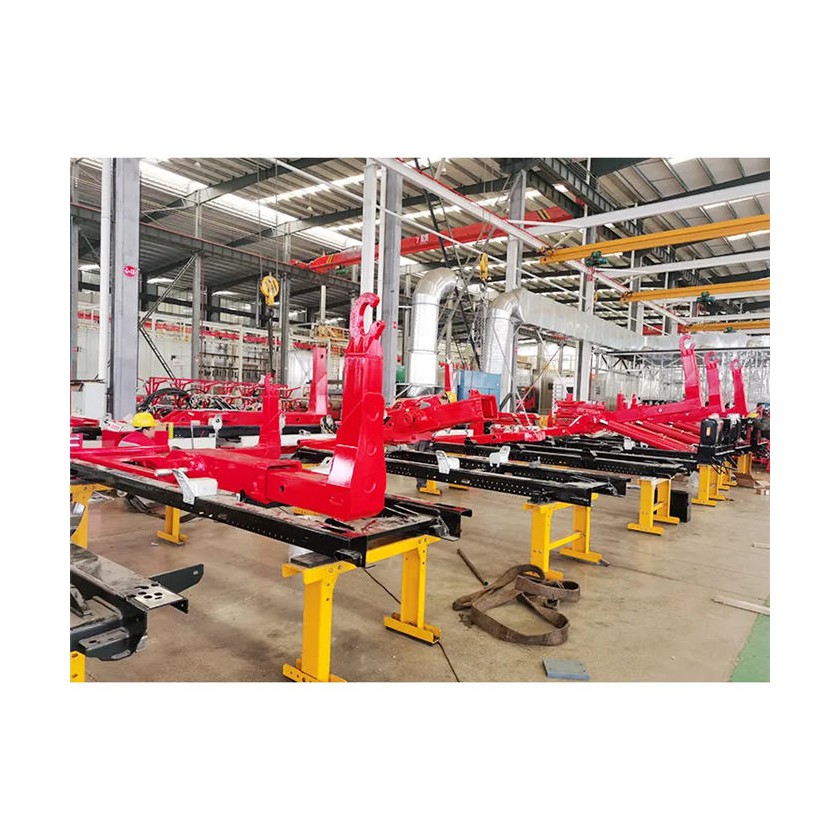

Hooklift technique features:

1 Advanced structure and hydraulic system design.

2 All the operations can be operated at a distance (30 meters range), and the operation is simple and convenient.

3. Anti-corrosion treatment of junction component filling: spray coating of steel structure with high quality paint; Metal parts (axial connections parts, hard oil pipes, flexible pipe fittings, bolt joints, etc.) are treated with anti-corrosion and zinc-plated.

4 In the parts of the friction set between the drawarm hook and the box body, integral cast parts are used in many places. Castings have good mechanical properties and excellent rubbing and smoothing properties

Secure

1) The total pressure of the system and each single valve block are equipped with overload protection.

2) Lift cylinder, slide cylinder, rear box lock cylinder and rear stability mounting are equipped with load holding valves.

Liquid pressure interlocking is arranged between the hook arm sliding, box body self-unloading, loading and unloading box body and rear box locking, etc.

To avoid misoperation.

Hook

High strength design, the whole system. The curved line of the contact surface fits the actual moving track, and the box is hung and unloaded

Simple and reliable; The hook is equipped with organic mechanical gravity safety to ensure safety and reliability

Electric Hooklift can load and unload containers, trailers and other means of transport, making logistics more efficient.