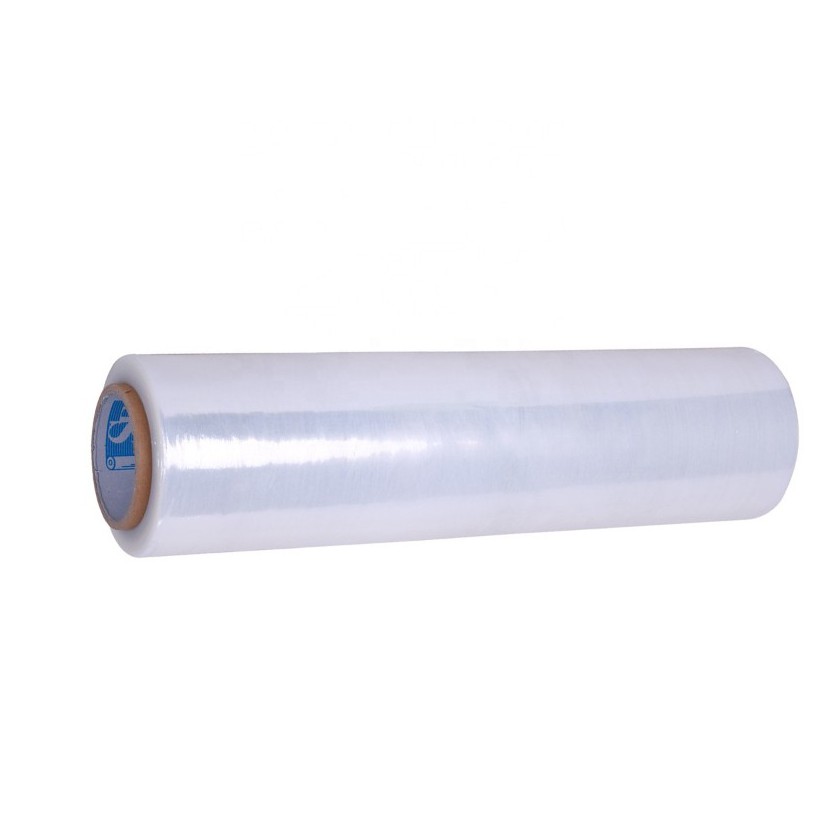

Biodegradable Stretch Film is a highly stretchable plastic film that is wrapped around items.

The elastic recovery keeps the items tightly bound. It is not only frequently used to unitize pallet loads but also used for bundling smaller items.

Types of Biodegradable Film include bundling Stretch Film, hand Stretch Film, extended core Stretch Film, machine Stretch Film and static dissipative film.

2. Biodegradable Stretch Film Functions

In pallet unitizing, Biodegradable Stretch Film can have several functions:

1) improved stability of products or packages, forming a unit load

2) more efficient handling and storage of unit loads

3) some degree of dust and moisture protection

4) some degree of tamper resistance and resistance to package pilferage

Making sure cartons stay on the pallet is an important consideration in warehouse distribution, especially as the demands for increased throughput continues to rise. Stretch wrapping is the most cost-effective way to keep loads secured, on a pallet.

Material: | PLA | Warranty: | Over 5 years |

Thickness: | 20mic-35mic. 15mic,17mic, 20mic, 23mic, 25mic, etc. | Color: | Transparent, black or any other color |

Width: | 100mm, 400mm,450mm, 500mm, etc. | HS CODE: | 3920109090 |

Length: | Any length, 300m, 400m, 500m, 1000m, 1500m, etc. | Packaging details: | 1rolls/ctn, 4rolls/ctn, 6rolls/ctn, etc. |

Core size: | 3 inches (76mm), 2inches (50mm), 1inch (25mm) | Logo print: | Paper core can be printed. |

Certificate: | ISO9001, SGS, ROSH, etc. | Production time: | 7-20 days. |

Quality grade: | Top Grade | Samples: | Free |

The customer provides the design manuscript (AI, CDR, PDF and other formats) - provides packaging solutions - the plate-making factory engraves the plate roller (plate making) - printing - inspection - compounding - aging - slitting - bag making - inspection - shipment.