Surface Mount Reflow Ovens are essential tools in modern electronics manufacturing, ensuring high precision and efficiency in soldering processes. These ovens are engineered to provide uniform heat distribution, precise control, and reliability in handling the complex demands of Surface Mount Technology (SMT).

Product Specification

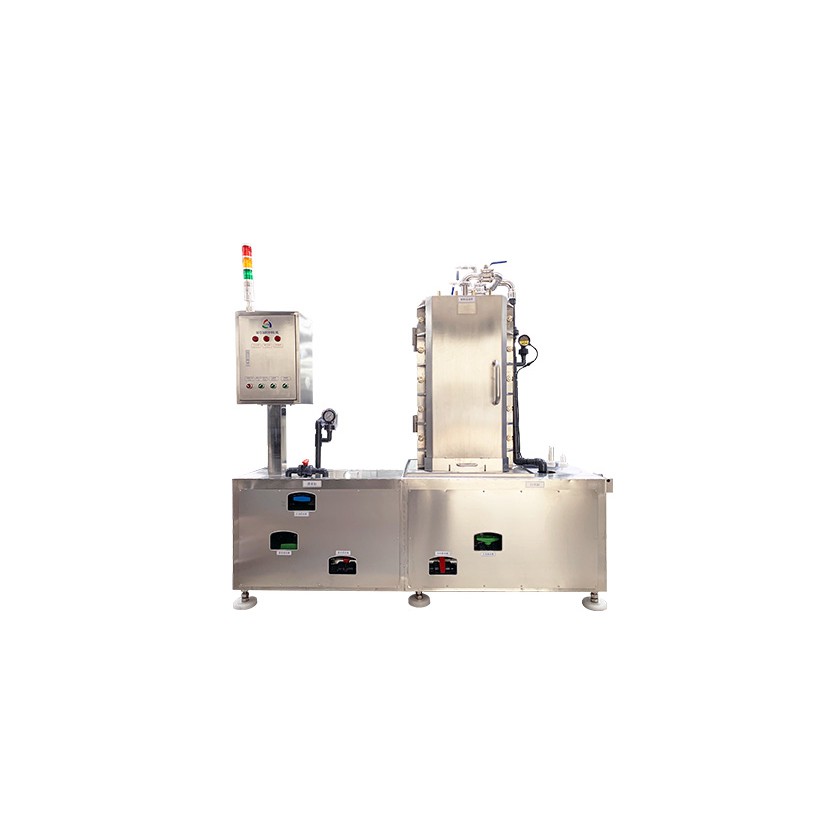

Name | SMT Reflow Ovens with Square Tower-TF2-F |

Appearance Size | L2000mm*W750mm*H2000士25mm |

Filtering Accuracy | 10μm |

Sewage Treatment Capacity | 70-150L/Min |

Air Supply Pressure | 3.0-5.0Kg/cm |

Visualization | Equipped with digital electronic pressure gauge,alarm prompt for maintenance of filter bag |

Total weight of the machine | About 1.0T |

Applicable Process | Resin Plug Hole Grinding, Deburring, Removing Copper Particles,Dry Film Pre-treatment, Solder Mask Pre-treatment, ENIG Pre-treatment, HASL Pre-treatment and other positions that need to be filtered |

Application

Soldering Surface Mount Devices (SMDs):

Surface Mount Reflow Ovens are vital in soldering SMDs onto printed circuit boards (PCBs), ensuring secure and reliable electrical connections between components and the PCB.

Printed Circuit Board Assembly (PCBA):

Reflow ovens are integral to the automated assembly of PCBs, providing precision soldering for multiple components simultaneously.

Mass Production of Consumer Electronics:

Surface Mount Technology is widely used in consumer electronics manufacturing, including smartphones, tablets, laptops, and wearables. Reflow soldering ensures reliable and high-volume assembly.

Automotive Electronics Manufacturing:

Automotive electronics, such as engine control units (ECUs), sensors, and infotainment systems, rely on Surface Mount Reflow Ovens to achieve durable and precise soldering, even under harsh conditions.

If you are interested in our products, please contact www.jynpcbm.com